Battery, Pneumatic, Electric, Hydraulic Torque Wrench Manufacturers | Industrial Bolting Equipment

24-Hours:

+86 132 6266 2908

Torque Tools

Torque Tools BTW-PC Turning Gear

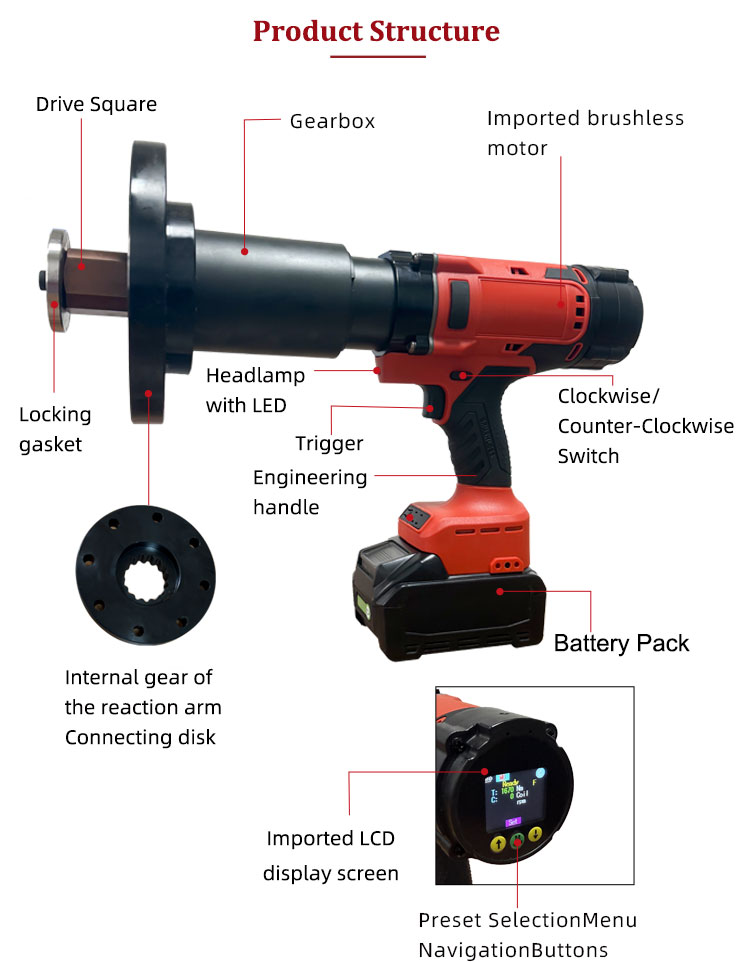

BTW-PC Turning GearBTW-PC Electric High-Speed Turning Gear Tool/Wrench

High-Efficiency Power Core

Equipped with a high-power brushless DC motor, it delivers robust power output for driving operations, ensuring long-term stable performance. Its low-maintenance design reduces operational costs, providing reliable support for high-intensity work scenarios.

High-Precision Torque Control

Repeatability accuracy up to ±3%. Compatible with 220V/50Hz AC power supply and designed to withstand grid fluctuations (220V ±40V). Features an intelligent self-calibration system, allowing the turning torque wrench to adapt effortlessly to any nut application.

Smart Software APP

Optional Bluetooth or WiFi modules enable data transmission, recording, tracking, and tightening result analysis.

Intelligent Control

Real-time torque and rotation angle display

Rotation count recording

Nut tightening/loosening count tracking

Automatic shutdown upon reaching preset torque with real-time torque value display

Reaction arm automatically retracts slightly for safe and convenient operation

User-Friendly Operation

Programmable preset torque for flexible operation

Large full-color LCD screen dynamically displays torque and angle data with intuitive clarity

Ergonomic handle design enhances ease of use

Premium Battery Cells

Lithium iron phosphate (LiFePO4) cells deliver stronger power output and superior thermal management. The next-gen 21700 power cells provide 50% more power while reducing temperature rise by 50%.

Safety & Reliability

Overload Protection: Automatically cuts power upon reaching set torque to prevent bolt breakage or tool damage.

Anti-Kickback Design: Mitigates reverse impact forces, reducing operator wrist injury risks (critical for heavy machinery maintenance).

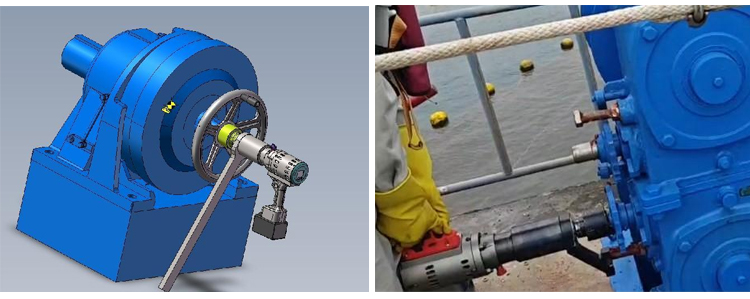

Efficient Collaborative Turning Workflow

Rapid Response & Repeatability: Electric operation triples efficiency compared to manual turning—e.g., completing flange bolt loosening/tightening cycles in under 2 minutes for daily 180° rotations in thermal power units. Supports multiple torque presets for different turning phases (e.g., looseness detection → formal turning → relocking).

Reduced Labor Dependency: Replaces traditional 2–3-person manual tightening teams with single-operator capability. Reaction arm design eliminates eccentric load risks.

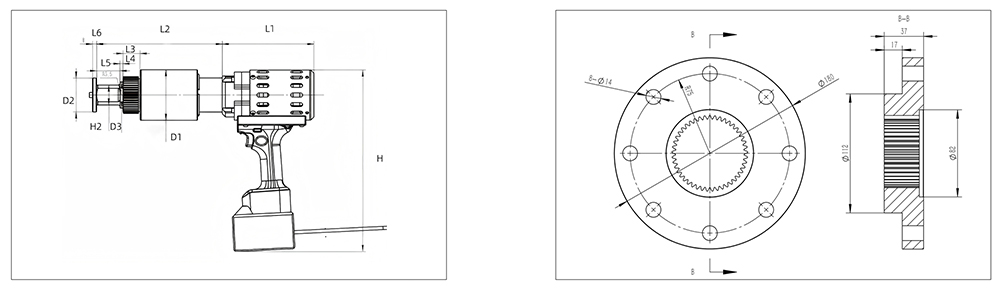

| Model | Min torque(N.m) | Max torque(N.m) | S | D1 | D2 | D3 | L1 | L2 | L3 | L4 | L51 | L6 | H1 | H2 | R | Weight | Max speed |

| mm | (Kg) | rpm | |||||||||||||||

BTW-PC-040 | 500 | 4000 | 3/4" | 80 | 65 | 50 | 178 | 300 | 33 | 5.5 | 45 | 8 | 348 | 38.1 | 3.5 | 10 | 8 |